A welding seam polishing machine, also known as a weld seam polisher or weld seam grinder, is a machine used to polish and finish welding seams on metal surfaces. It is primarily used in industries such as metal fabrication, automotive, aerospace, and shipbuilding, where high-quality welding finishes are required.

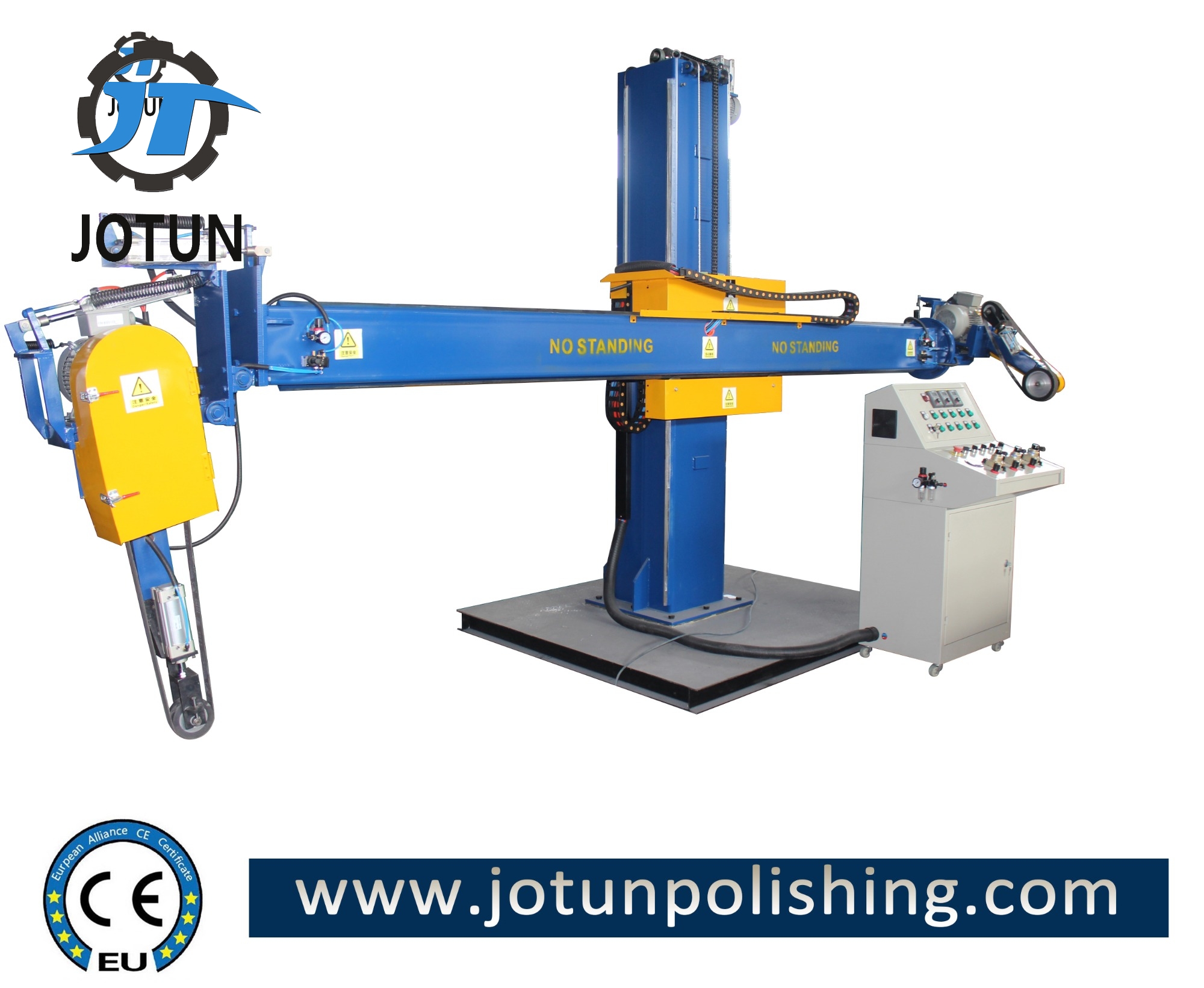

The main purpose of a welding seam polishing machine is to remove welding imperfections, such as excess weld material, spatter, and roughness, and create a smooth and polished surface. The machine typically consists of the following components:

1.Polishing Head: The polishing head is the main component of the machine and is responsible for performing the polishing operation. It usually consists of abrasive belts, grinding wheels, or polishing discs that rotate or oscillate to remove material from the weld seam.

2.Workpiece Holder: The workpiece holder secures the metal workpiece in place during the polishing process. It may have adjustable clamps or fixtures to accommodate different sizes and shapes of workpieces.

3.Control Panel: The control panel contains the necessary controls and settings for operating the welding seam polishing machine. It allows the operator to adjust the speed, pressure, and other parameters of the polishing operation.

4.Power Supply: The machine is typically powered by electricity and requires a reliable power supply to operate.

The welding seam polishing machine works by applying abrasive materials or polishing compounds to the welding seam surface. The polishing head, driven by a motor, moves back and forth or rotates while exerting pressure on the workpiece. This abrasive action gradually removes material from the weld seam, smoothing out imperfections and creating a polished finish.

The machine may have multiple stages or abrasive belts of varying grit sizes to achieve the desired level of polish. Coarser grits are used initially to remove weld spatter and roughness, while finer grits are employed for final polishing and achieving a smooth surface.